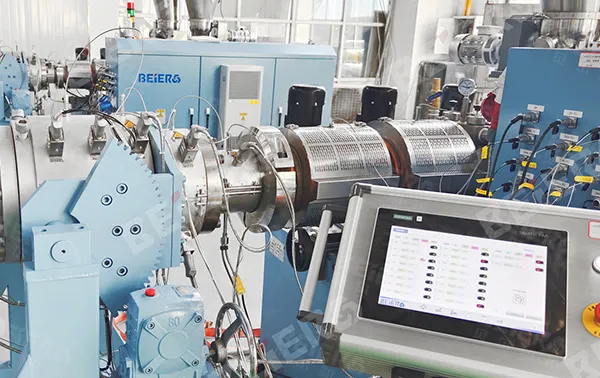

PVC-O pipes (Biaxially Oriented PVC Pipes) represent an innovative advancement in high-pressure piping systems, engineered through a specialized molecular orientation process that rearranges the polymer structure of PVC-U material along both the circumferential and longitudinal axes. This biaxial orientation enhances the material’s crystalline alignment, resulting in superior tensile strength, impact resistance, and fatigue endurance compared to conventional PVC. As the pinnacle of modern pressure pipe technology, PVC-O pipes deliver exceptional hydraulic efficiency and long-term durability, establishing them as the optimal choice for high-pressure water transmission infrastructure in contemporary engineering applications.

Half thickness of PVC-U pipe. Raw material cost effective.4 Times impact resistance to external loads

Smooth inner wall. Higher water conveyance.

Increased hydraulic capacity

Between 15-40% more hydraulic capacity than PVC-U, HDPE

Optimal environmental performance

Energy efficient

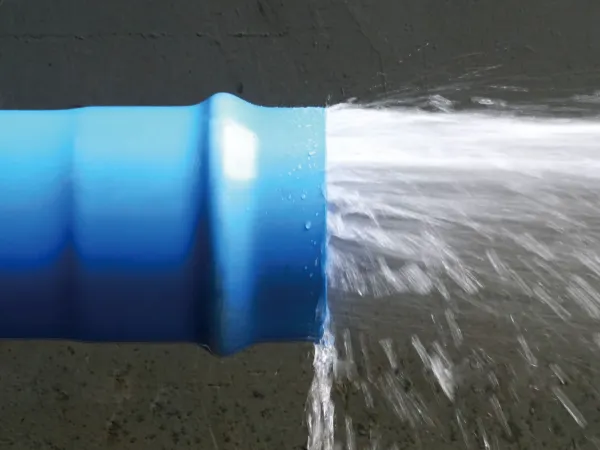

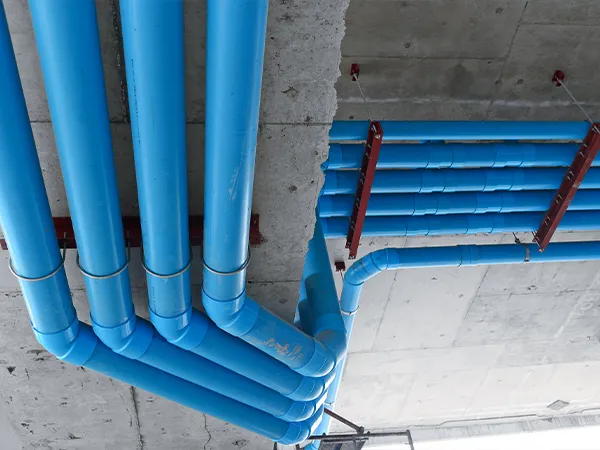

PVC-O pipes are primarily used for the transportation of potable water, irrigation, water conservancy projects, landscaping, drinking water supply in rural areas, fire protection systems, factories and mines, chemical corrosion prevention, sewage systems, reclaimed water, and more—specifically for conveying high-pressure water.